Internet of things (IoT) Solution in Oil & Gas Industry

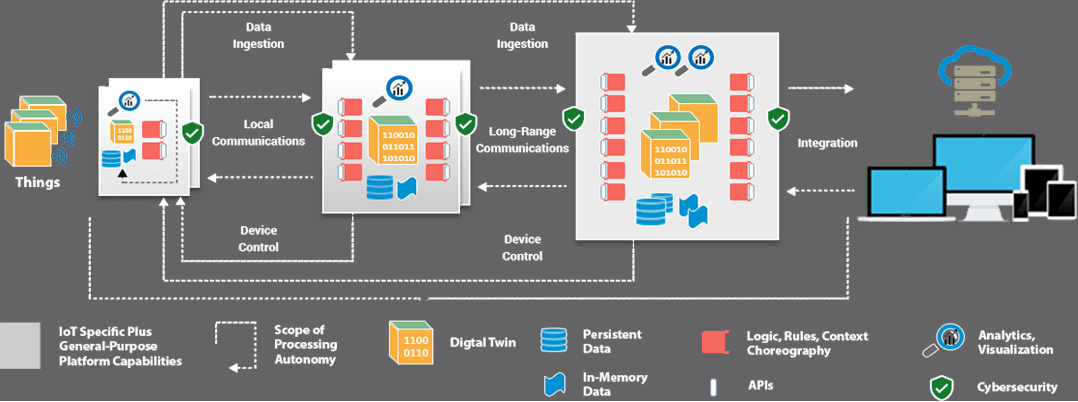

The Internet of Things(IoT) in oil and gas industry is the smart technology used to create a network of physical devices that can connect to the internet, and be monitored and controlled through the internet. These things(devices) collect data and pass data through a series of gateways, concentrators or other telemetry devices, then integrated with other backend systems to process/analyse and store data.

Extracting fuels from the ground and transporting them to the refinery to the end-user is a complex and critical task. Drilling equipment, pipelines, transportation and logistics – there are too many points to monitor along the way, with each one being critical, and potentially dangerous, next to another one. All the parts of the Oil and Gas value chain – Upstream, Midstream, or Downstream, every sector has its adaptions to the IoT in Oil and Gas.

Together with our partners and combining with new technologies, PEAPROS has the ability to deploy the IoT solutions in both local and cloud. Some IoT solutions summaried from our project experience, are listed below.

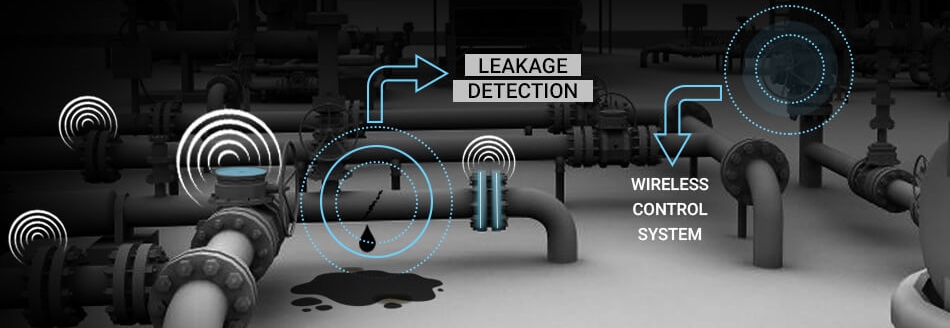

Leak detection

Detecting leaks in the oil and gas pipelines is crucial to prevent losses and accidents in factories. Petroleum products being volatile substances can easily catch fire and explode. With flow and pressure metering solution of IoT leaks in pipelines can be detected in real-time. This solution can also be used to identify leakage of toxic and combustible gases along with asphyxiants such as methane that are generally found in such industrial setups. IoT real-time alert system can alarm operators about these leaks and help them to take necessary actions to prevent any hazardous conditions.

Oil well/tanker monitoring

Real time Oil Well/Tanker Monitoring Solution is very helpful for the Oil & Gas Industrialists. As this is an IoT driven solution, one gets instant data assist that helps in taking preventive measures. This helps in optimizing business operations for higher revenues. One miscalculation in keeping oil well/tankers protected from flammable substances can cause major mishaps in the surroundings. With Oil Well/Tanker Monitoring Solution, monitoring tank level & temperature, remote oil wells, oil tanks, water pressure and more is easy. The solution helps in saving both time and money while bringing advantageous results to related business that fail to optimize its potential.

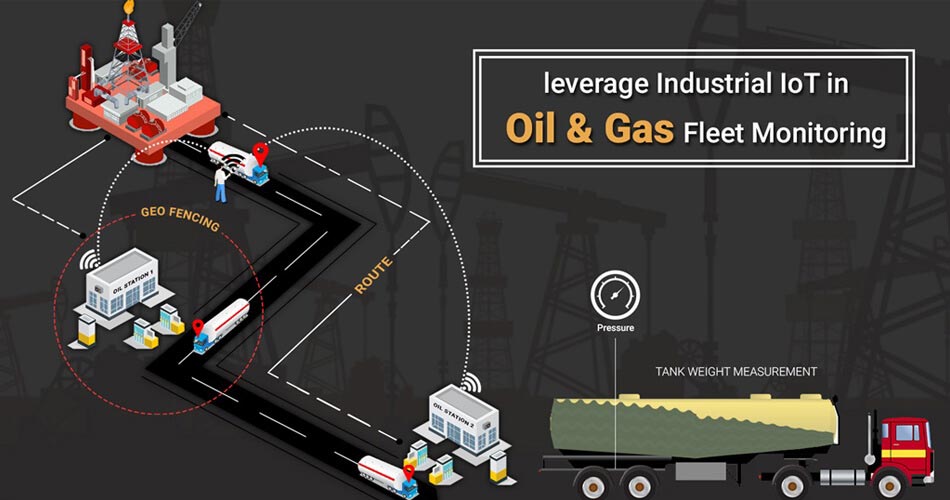

Fleet Monitoring

Real time fleet location is a very helpful feature for fleet managers. With IoT based Fleet Monitoring Solution, one can get crucial data assist. This helps in optimizing business operations. The solution streamlines Logistics functions by using instantaneous sensor data and alerts. Now, choosing hassle free delivery routes and ensuring driver safety at all levels is easy. Utilize multiple vehicles with highly coordinated logistics. And, reduce unnecessary fuel consumption, cut down chances of transport blowout, enhance productivity and boost profits, all within a reasonable time frame and budget.

Benefits of IoT in Oil & Gas

IoT solution is not only included the new "smart" devices and technologies, but also can stay with its current legacy technology like SCADA, PLC, DCS, HMI Devices, and develop new business models.

- Real-time data from IoT endpoint device.

- Equipment Health Check And Preventive Maintenance

- Maintain A Sustainable Environment

- Remote Asset Tracking & Management